Any Bulk Food Product –

any Critical Defect.

We are pushing the boundaries of what is possible and setting new standards in the detection and selection to ejection of foreign objects and food defects. Using Deep Neuronal Network technology in combination with the well proven Chemical Imaging Technology (CIT® Gen3), Sherlock Hypernova intrinsically detects, learns, processes and optimises data from the sorting process, opening up completely new dimensions in food sorting.

Thanks to the latest generation of Chemical Imaging Technology (CIT® Gen3) in combination with high-resolution color cameras, both the smallest foreign bodies and product defects – organic or inorganic – can be sorted out with unprecedented accuracy. This is done with maximum conservation of product and energy resources.

The new Sherlock Hypernova has been specially developed for sorting small-sized products/foodstuffs.

The modular design allows to be configured specifically for each product and thus tailored to individual requirements.

Maximum Flexibility, Efficiency and Precision –

Welcome to the Future of Food Sorting!

- 3-way sort for optimization of yield

- High precision defect sorting

- Highest food safety – FM removal independent of size, shape, weight and density

- Small line footprint

- Easy integration at any point of the production line.

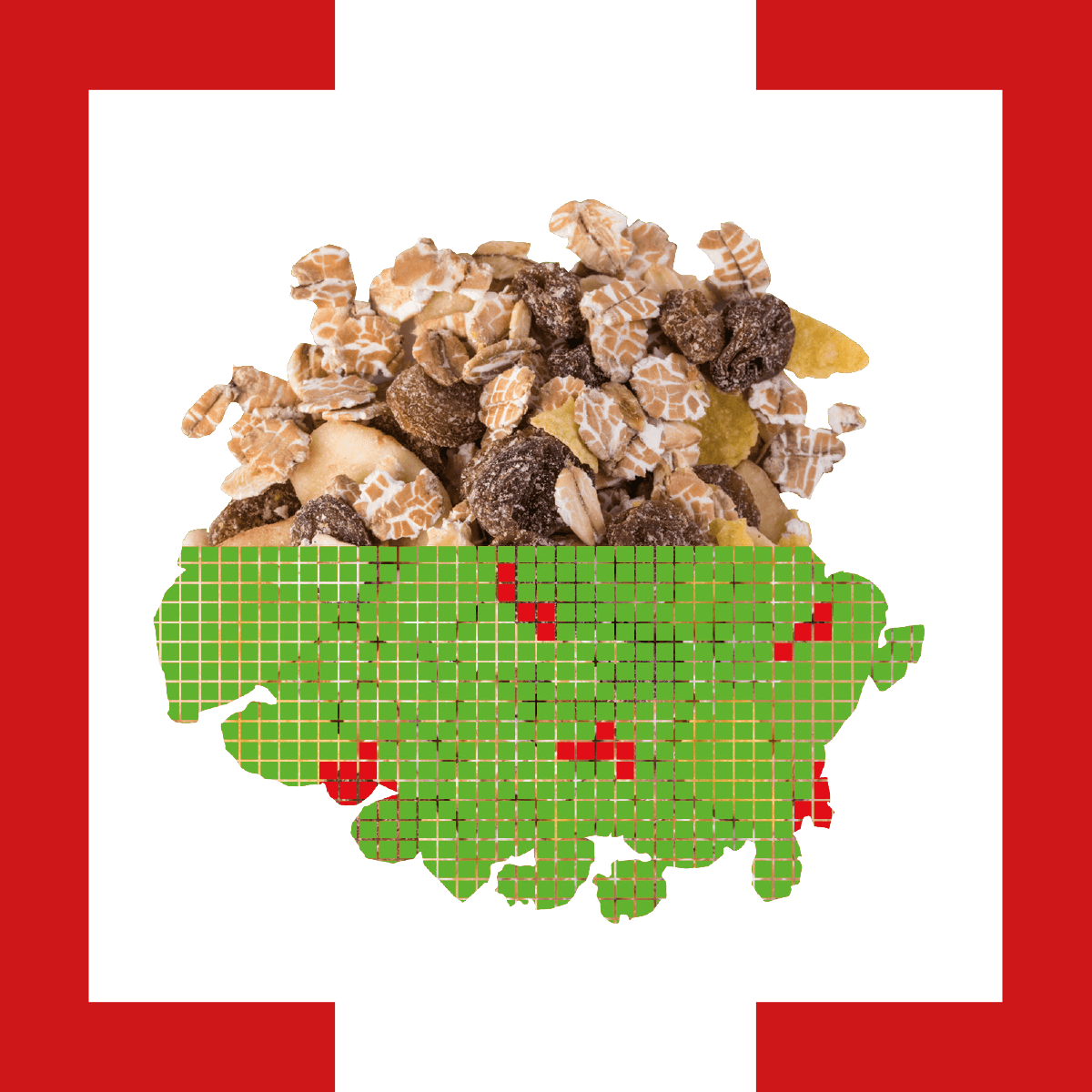

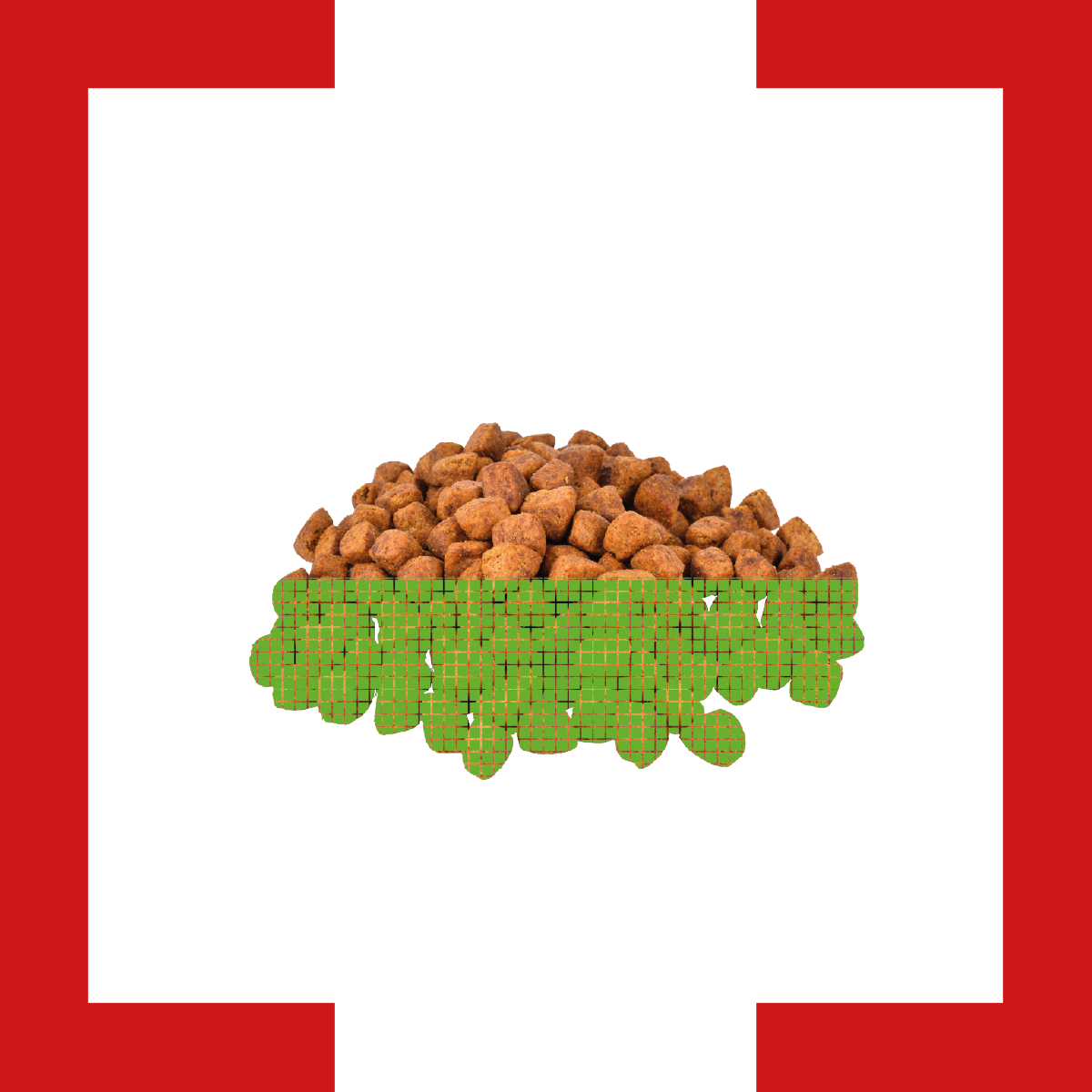

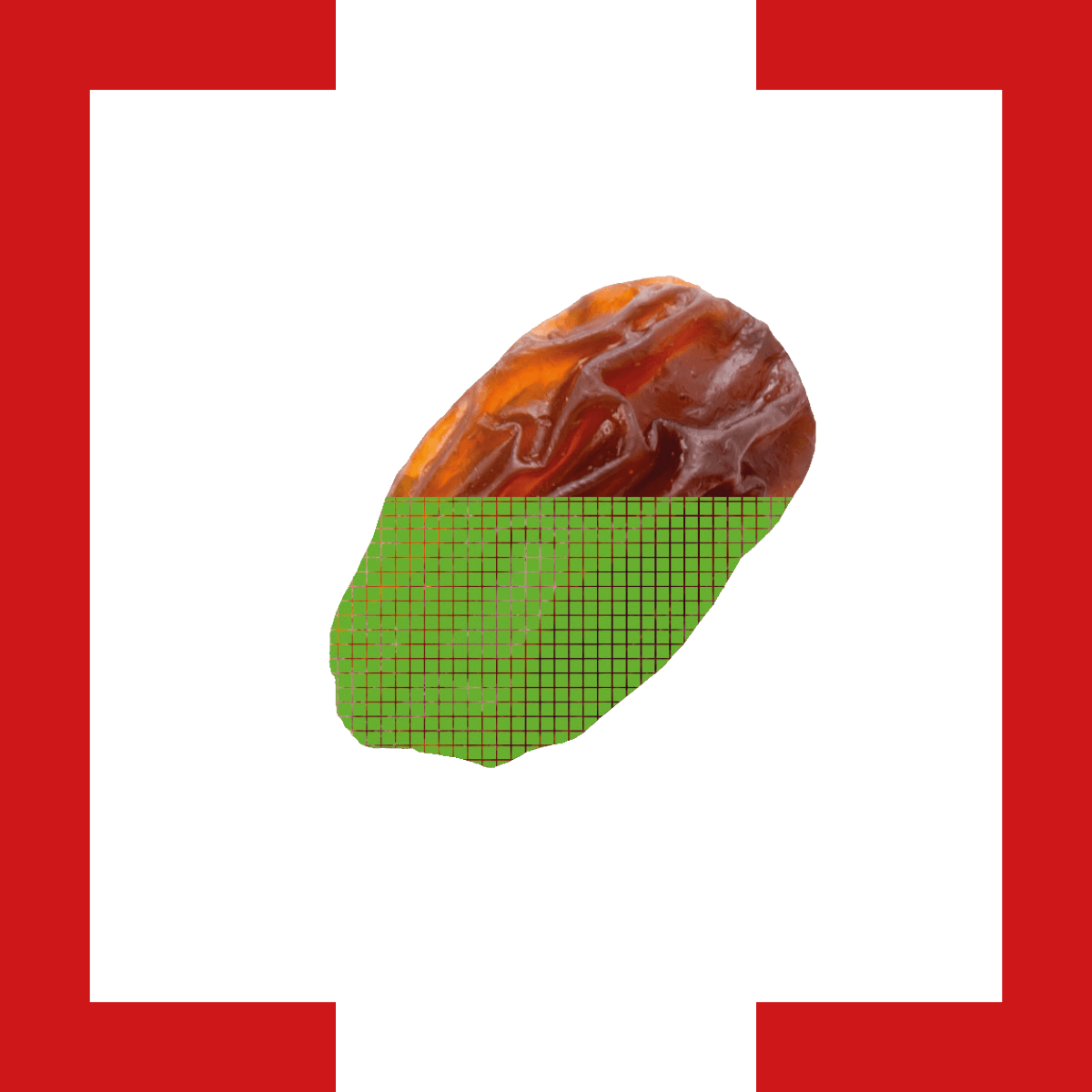

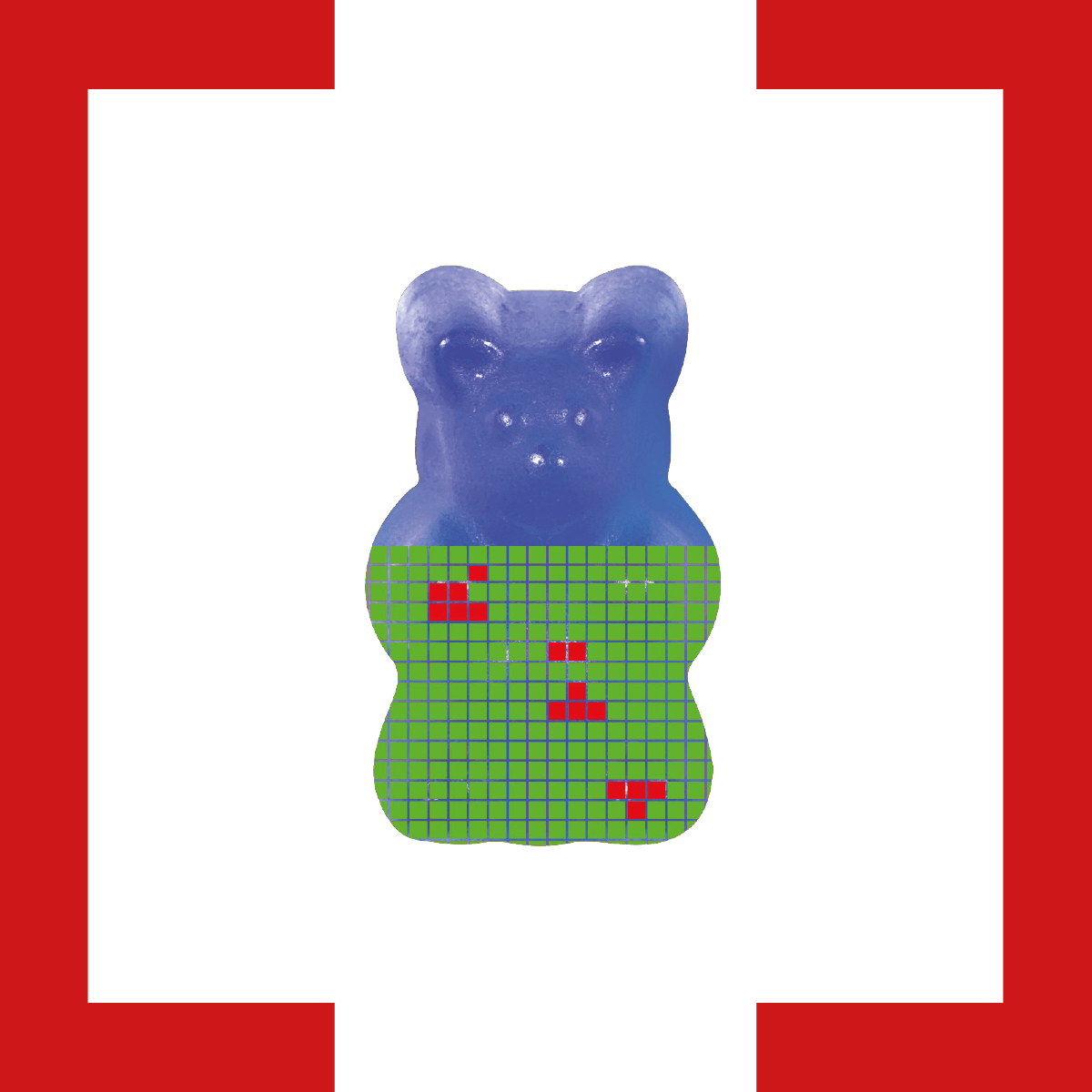

Some Application and Defect Examples

- All types of foreign material

- Rancidity

- Bitter Almonds

- Moisture content

- Oil content

- Chip & Scratch

- Insect damage

- Mummies

- Webbing

- Gummies

- Embedded shells

- Butterballs

- Shrivel

- Mold

- Visible and invisible rot in nuts

Technology that Makes the Difference

CIT’s chemical inspection capabilities brings us to new levels and possibilities of product inspection compared to any other optical eye out there such as lasers, various amount of cameras or Xray. Where other optical eyes focus on trading off the amount of bad in good vs good in bad; CIT’s approach is seeing and removing it with the highest reliability of the industry, no matter what product or defect and this at consistent levels even if there are seasonal product changes or product variety changeovers. CIT does not need any operator to constantly be monitoring and keeping the machine in balance.

For the first time, artificial intelligence in the most versatile form of Deep Neuronal Networks is applied in real time to analyse the collected image data. It creates algorithms that enable the detection of even the smallest visible product defects as well as defects invisible to the human eye, fast enough to eject them from high-speed product flows. This new disruptive technology opens unimaginable applications and performance levels for food processors.

InlineFOODLab 4.0 allows processors to optionally get quantitative chemical data of the product and the most reliable real-time inline quality data available in the industry. For example dry matter values in potato products. These chemical data can be combined with color or shape defect levels as well as with size values of the objects. Additionally, any foreign material can be recorded. This allows quality managers to have better tools to control the raw material as well as the finished product.

The synthesis of a new designed, highprecision air separation technology with a flap separation, specifically engineered for maximum food safety, marks a revolutionary advancement: It precisely classifies acceptable products, foreign bodies, and defect products into three categories in just one pass. The core of this innovation is the use of precise sensor data, captured by the latest generation of Chemical Imaging Technology (CIT Gen 3). This technique allows for the determination of the optimal sorting strategy in real-time, enabling a significant increase in yield while providing unparalleled food safety. This cutting-edge eject technology opens up an unprecedented level of quality and safety, redefining the limits of what has been possible until now.