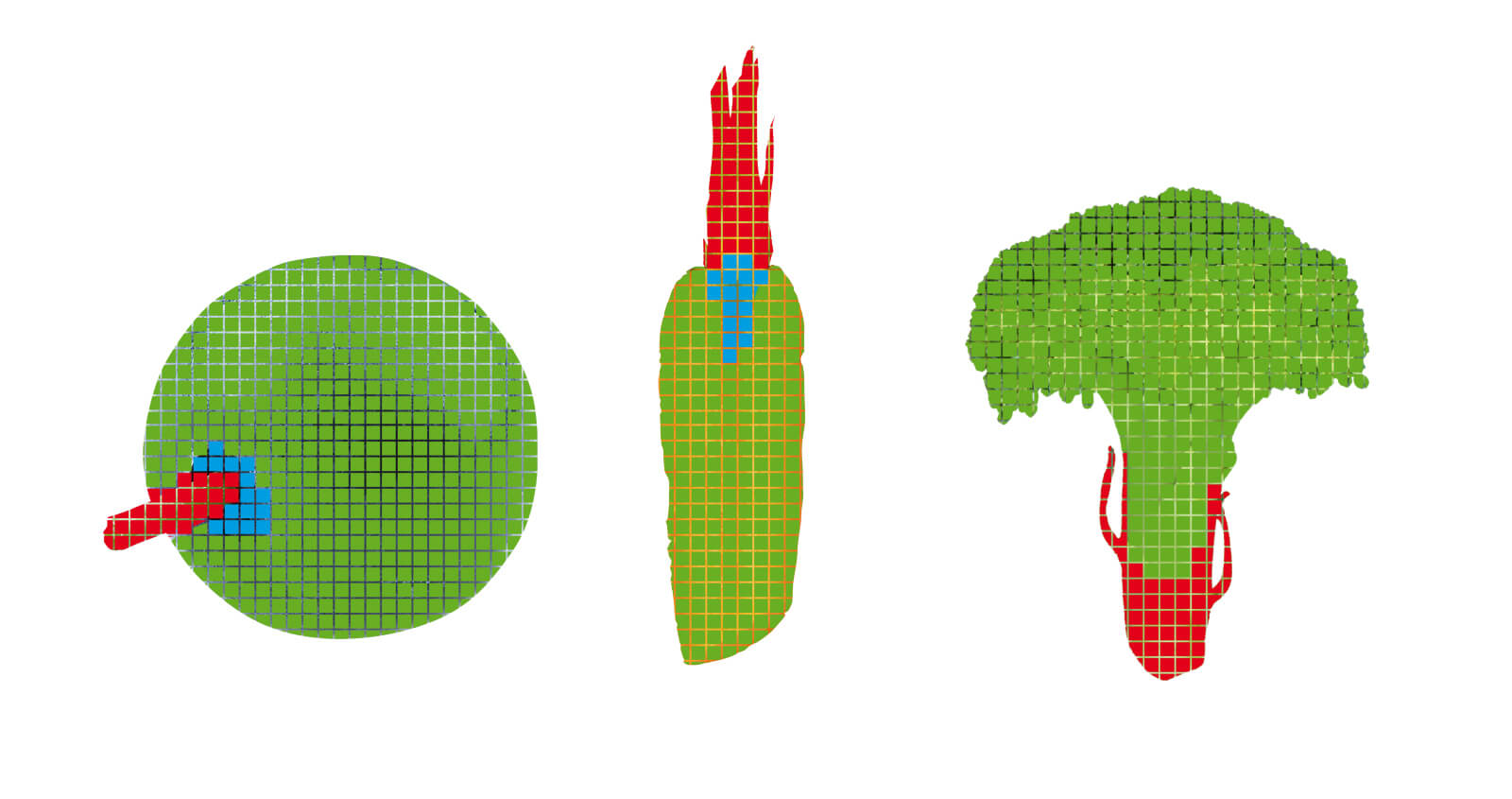

This revolutionary approach enables unmatched precision in detecting contaminants such as plastics, shells, and stones, ensuring the highest food safety standards. It identifies both internal and surface defects, including frost-damaged, discolored, or underripe pieces, guaranteeing optimal product quality. At the same time, its ability to maximize usable product significantly reduces waste, increasing yield and profitability. By optimizing the sorting process and minimizing the need for manual intervention, CIT® enhances production efficiency and throughput, making frozen food processing more cost-effective and reliable.

With CIT®, processors gain a decisive competitive edge, ensuring consistent product quality while lowering costs and reducing waste – a game-changer for the frozen food industry.

The association “Great Hope for Children” has a clear mission: To provide children and young adults in Nairobi with an education in order to break the cycle of poverty that has been recurring for generations. Around 150 children, of which approximately 70 are orphans, are currently being cared for.

„We at Insort are proud to accompany and support Great Hope for Children on all levels.“

Eva Jeindl-Gombocz, CFO Insort