Unmatched Food Safety Performance.

The Sherlock Hybrid enables clear determinations to be made about whether to remove objects by means of air (optimal yield for product defects) or flaps (most reliable removal method for foreign bodies), and that separates your product reliably into 3 quality grades.

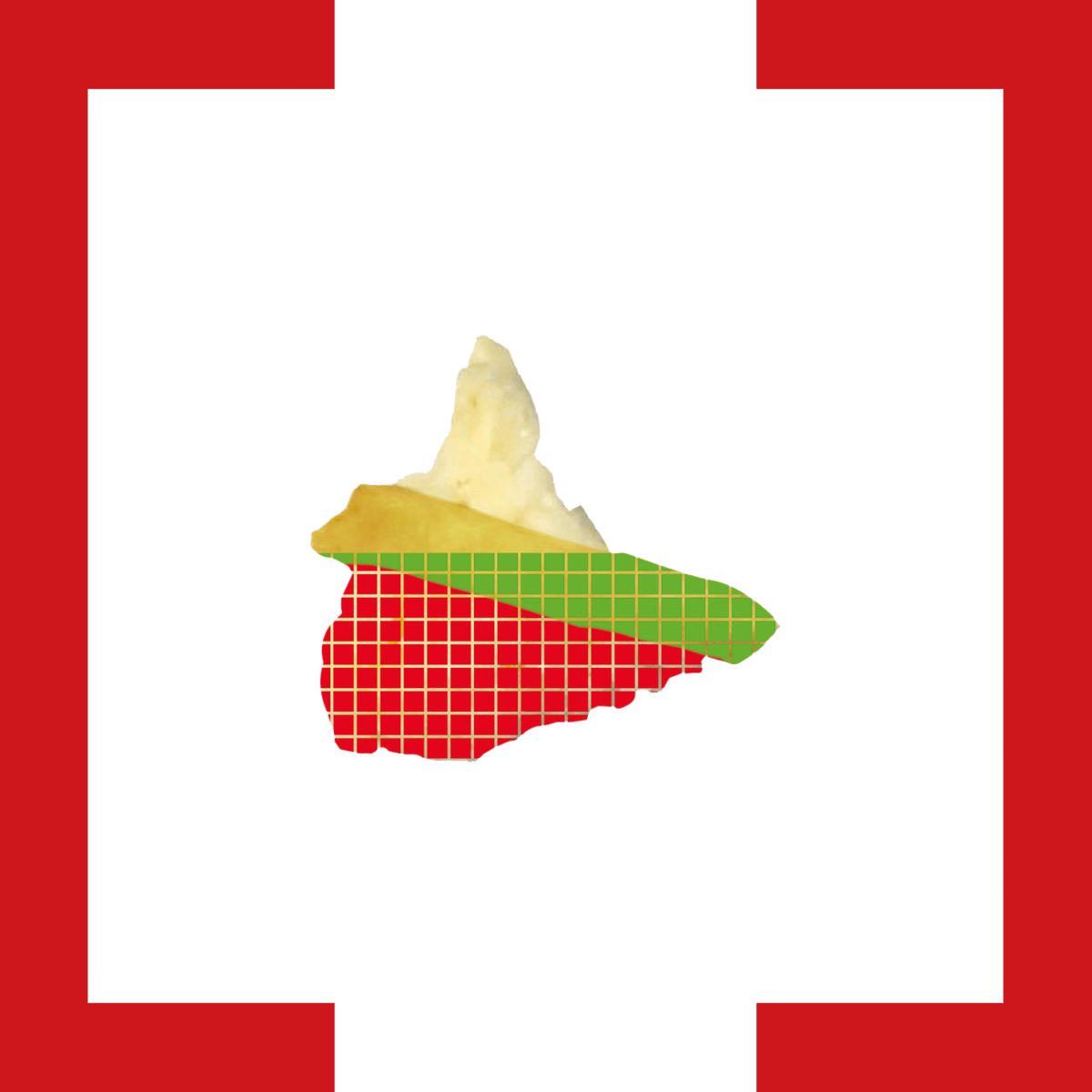

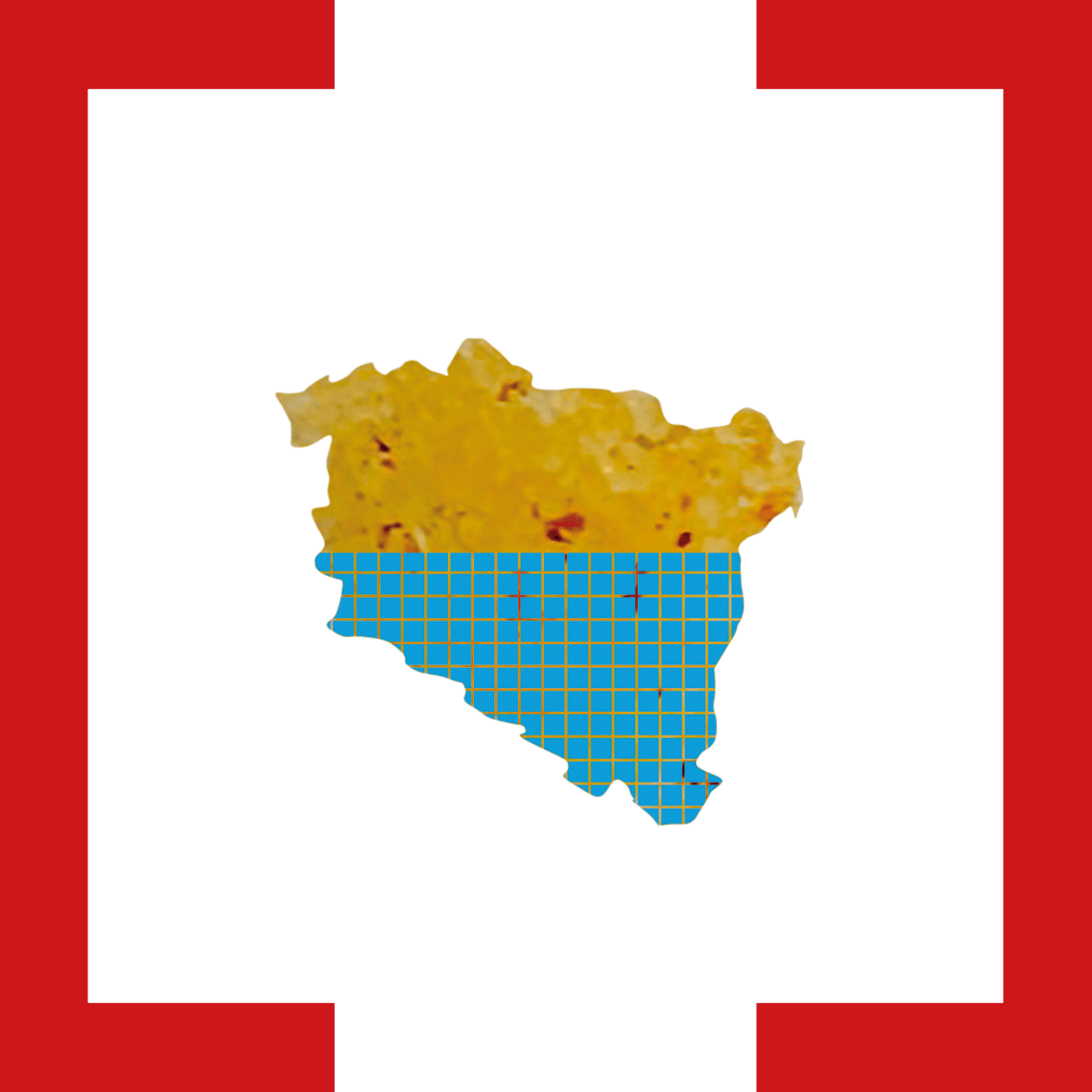

The precision sophisticated Chemical Imaging Technology (CIT® Gen3) has been further enhanced in the Sherlock Hybrid by adding high resolution color camera technology. CIT® enables assessment of the whole near infrared spectrum and analysis of objects’ chemical composition, regardless of color, shape, surface or density. High-resolution color cameras synthesize additional information on color, shape and surface for each individual object.

It is this high density information that enables clear determinations to be made about whether to remove objects by means of air (optimal yield for product defects) or flaps (most reliable removal method for foreign bodies), and that separates your product reliably into 3 quality grades.

The Sherlock Hybrid is tailored for sorting potato products like fries, ensuring superior quality by detecting foreign materials and inconsistencies.

Advanced Technology for Unmatched Food Safety Performance.

- Further enhanced performance in terms of detection reliability

- Latest Chemical Imaging Technology CIT® Gen3

- Highest defect detection reliability by means of high resolution true color rgb cameras

- Artificial intelligence applied in real time

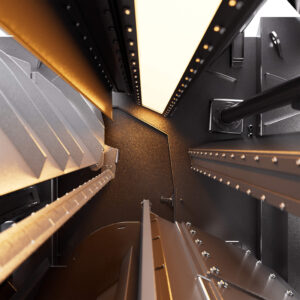

- Newest generation lighting system

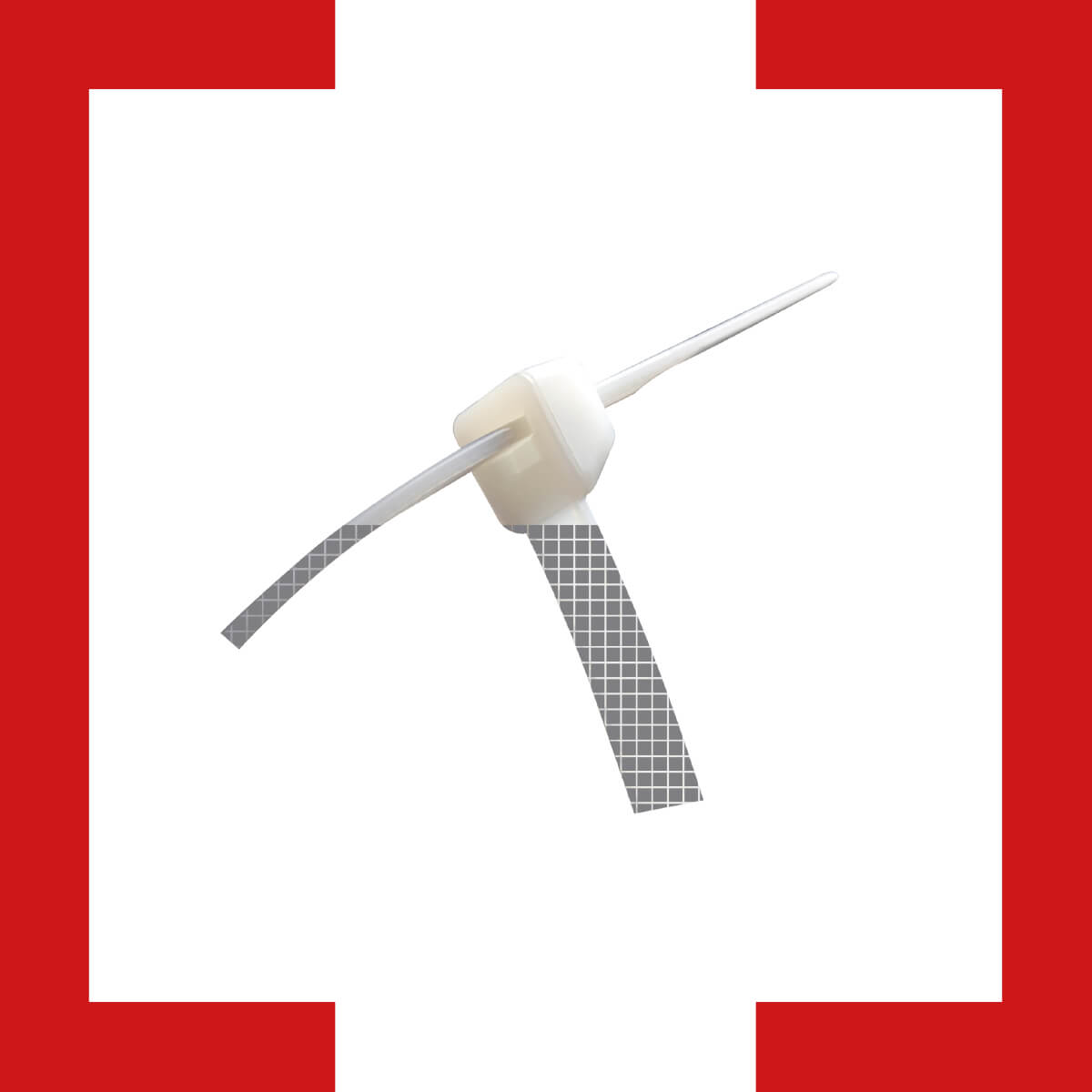

- High Speed Air Valve System

- Drop Gate System

- Detection of Foreign Bodies

- Detection of Color Defects

- Detection of Shape Defects

- Detection of Chemical Defects

(e.g. Sugar Ends, Glassiness) Patent Granted - Sorting by Size (Length and Width)

- 2-Way and 3-Way Sorting

- Hybrid Rejection System

– High Speed Air Valve System

– Dropgate System - Size Statistics

- Defect Statistics

- Reject Statistics

- Remote Access

Technology that Makes the Difference

CIT’s chemical inspection capabilities brings us to new levels and possibilities of product inspection compared to any other optical eye out there such as lasers, various amount of cameras or Xray. Where other optical eyes focus on trading off the amount of bad in good vs good in bad; CIT’s approach is seeing and removing it with the highest reliability of the industry, no matter what product or defect and this at consistent levels even if there are seasonal product changes or product variety changeovers. CIT does not need any operator to constantly be monitoring and keeping the machine in balance.

For the first time, artificial intelligence in the most versatile form of Deep Neuronal Networks is applied in real time to analyse the collected image data. It creates algorithms that enable the detection of even the smallest visible product defects as well as defects invisible to the human eye, fast enough to eject them from high-speed product flows. This new disruptive technology opens unimaginable applications and performance levels for food processors.

InlineFOODLab 4.0 allows processors to optionally get quantitative chemical data of the product and the most reliable real-time inline quality data available in the industry. For example dry matter values in potato products. These chemical data can be combined with color or shape defect levels as well as with size values of the objects. Additionally, any foreign material can be recorded. This allows quality managers to have better tools to control the raw material as well as the finished product.