CIT® – Chemical Imaging Technology by Insort

Revolutionizing Food Sorting and Quality Control: CIT by Insort is transforming the way the food industry approaches quality and safety. By combining advanced chemical imaging with high-speed sorting, this innovative technology ensures that only the best products make it to the market—helping businesses achieve precision, efficiency, and sustainability in their operations.

Chemical Imaging Technology (CIT) by Insort is an innovative optical sorting solution that combines cutting-edge hyperspectral imaging with real-time data processing to ensure unmatched accuracy and efficiency in food inspection. This state-of-the-art technology analyzes products based on their chemical composition, structure, and external appearance, setting new standards for quality control in the food industry.

Key Features of CIT Technology

- Chemical Composition Analysis:

Using near-infrared (NIR) hyperspectral imaging, CIT identifies key chemical properties such as moisture, sugar, starch, fat, and protein content in every item. - High-Speed Sorting:

CIT operates at industrial speeds, delivering real-time sorting and inspection without compromising precision, making it ideal for large-scale processing. - Comprehensive Inspection:

The technology evaluates both the chemical properties and the physical attributes of food products, including size, shape, color, and surface texture. - Detection of Foreign Materials and Defects:

CIT accurately identifies contaminants like plastic, glass, metal, or stones and detects defects such as mold, discoloration, or internal rot that compromise product quality. - Advanced Algorithms for Precision Sorting:

Proprietary algorithms process imaging data to classify or reject items based on customizable criteria tailored to specific product requirements.

Applications

CIT technology is trusted across multiple industries for its ability to ensure superior quality and product safety, including:

- Potato Processing: Identifying internal defects like sugar ends, rot, or greening.

- Nuts and Seeds: Detecting shell fragments, foreign materials, or defective kernels.

- Fruits and Vegetables: Spotting chemical or physical defects, contaminants, or ripeness issues.

- Meat Processing: Analyzing fat and protein content for better control over product quality.

Benefits of CIT Technology:

- Enhanced Quality Control: Detects both visible and invisible defects with unparalleled accuracy with more than 99,5%.

- Minimized Waste: Reduces unnecessary rejection of good products while ensuring defective ones are removed.

- Increased Efficiency: Operates at high speeds, making it a cost-effective solution for industrial food production.

- Customizable Solutions: Flexible configuration to meet specific product and production needs.

Artificial Intelligence

Applied in Real-Time

Insort leverages Artificial Intelligence (AI) to enhance the efficiency and precision for food sorting. By integrating AI into their systems, Insort takes food inspection to the next level, enabling real-time analysis and decision-making with unparalleled accuracy.

How AI Powers Insort's Food Sorting

Data Processing and Interpretation

AI algorithms analyze imaging data generated by RGB and CIT in real time. These algorithms can interpret complex patterns in the properties of food items, enabling accurate identification of defects, contaminants, and foreign materials.

Deep Learning Models

Insort employs deep learning models trained on extensive datasets of food products. These models recognize subtle differences between acceptable and defective items. AI continuously improves through machine learning, becoming better at detecting new defect types or contamination scenarios over time.

Real-Time Decision Making

AI ensures that sorting decisions are made instantly, maintaining high-speed processing without compromising accuracy. This is critical for industries handling large volumes of food products.

Continuous Optimization

AI-powered systems are self-optimizing, learning from new data and adapting to changing conditions, such as variations in product quality or seasonal differences.

AI is at the heart of Insort’s commitment to revolutionizing food safety and quality control. By integrating advanced algorithms, Insort delivers smarter, faster, and more reliable solutions for the food industry.

AI is at the heart of Insort’s commitment to revolutionizing food safety and quality control. By integrating advanced algorithms, Insort delivers smarter, faster, and more reliable solutions for the food industry.

Inline FoodLab 4.0

Advancing Real-Time Food Quality Analysis

The Inline FoodLab 4.0 is Insort’s groundbreaking inline analysis system, developed to meet the highest standards of food safety and quality with exceptional cost efficiency. Launched in 2020 as part of a Horizon 2020 project, this innovative platform builds on Insort’s Sherlock Food Analyzer to provide real-time quality data acquisition directly during the sorting process. Designed with Industry 4.0 principles, the Inline FoodLab 4.0 integrates seamlessly across production, process control, and quality assurance, empowering food producers to achieve optimal efficiency and consistent product quality

Real-Time Data for Process Optimization

Inline FoodLab 4.0 enables precise, real-time quality analysis and documentation, offering comprehensive insights into key metrics such as dry matter content. This capability transforms quality control by providing actionable data during production. Particularly impactful in the potato industry, it allows producers to make informed, data-driven decisions to improve yield, enhance product quality, and reduce waste. Its versatility also supports applications across other food sectors, providing unmatched value for food producers.

Seamless Data Integration with Advanced Communication

The Inline FoodLab 4.0 features advanced data communication using the OPC UA protocol, ensuring secure and standardized integration with customer databases. To further enhance connectivity, Insort partners with SECOMEA to offer a solution for secure remote maintenance and data access. This setup guarantees robust cybersecurity while providing producers with real-time insights and operational flexibility.

High-Frequency Measurements for Maximum Precision

Capable of capturing up to 400,000 data points per hour, the Inline FoodLab 4.0 delivers an unprecedented level of precision and detail in quality analysis. By leveraging high-frequency measurements, the system minimizes the uncertainty associated with natural product variability. This data-driven approach enables producers to detect quality variations in real time, optimize processes, and maintain product consistency. Large sample sizes, combined with statistical rigor using Student’s t-distribution, ensure unparalleled accuracy and reliability, setting a new standard in food quality assurance.

Inline FoodLab 4.0 redefines food quality analysis by seamlessly integrating sorting with real-time data acquisition. Its innovative design enables producers to enhance product consistency, maximize yields, and meet stringent quality standards—making it an essential solution for the food industry of tomorrow.

CI-LED

Intelligent Lighting for Maximum Sorting Accuracy

With CI-LED, Insort introduces a completely new lighting system for food sorting. This LED-based technology replaces traditional halogen lamps and reduces the energy consumption of infrared lighting by up to 80% – while maintaining exceptional light stability and consistently high image quality.

Extremly Stable Light Spectrum

The specially engineered CI-LED light path provides an extremely stable light spectrum in the 1000–1650 nm range. Light intensity fluctuations remain under 2% – compared to the previously common 10%. Combined with a high-resolution HSI camera, this results in even more precise imaging and significantly improved defect detection – even at high line speeds and during extended operation.

Reduced Heat Generation

CI-LED also reduces heat generation within the system – a feature that is especially important for many customers. Lower temperatures protect mechanical components, extend their service life, and prevent product residues from burning onto the optical path. In addition, CI-LED is virtually maintenance-free, eliminating the need to replace halogen rod lamps.

Modular Ejection Technology

Maximum Sorting Efficiency & Food Safety

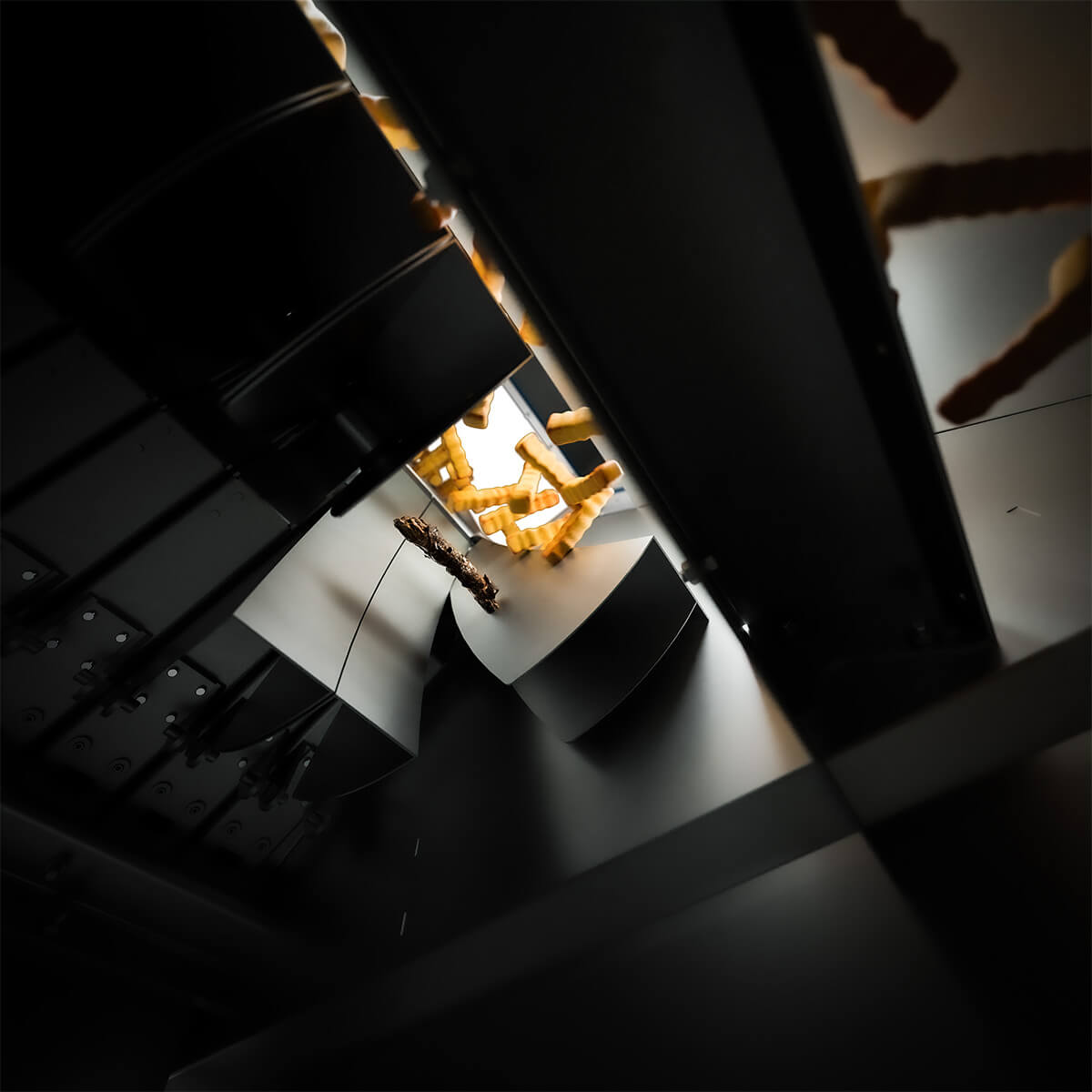

Insort’s Modular Ejection Technology represents a groundbreaking advancement in food sorting, combining high-precision air separation with mechanical flap separation to achieve unmatched sorting efficiency and food safety. This innovative system ensures precise classification of products into three distinct categories—acceptable products, foreign bodies, and defect products—in just a single pass, setting a new industry standard for accuracy and yield optimization.

Hybrid Sorting for Maximum Accuracy

Recognizing the need for tailored sorting solutions, Insort developed a patented hybrid sorting approach that combines the strengths of two key ejection methods:

- High-precision air nozzles for the accurate removal of small defects and foreign materials.

- Mechanical flaps for ejecting larger foreign objects, minimizing unnecessary product loss.

The Future of Food Sorting

By integrating real-time sensor analysis including CIT, AI-powered adaptability, and precise hybrid ejection mechanisms, Insort’s Modular Ejection Technology redefines the boundaries of food sorting. This cutting-edge innovation not only ensures superior food safety but also significantly enhances efficiency and yield—making it the most advanced ejection system available in the industry today.

Zero Touch Reject Technology

Maximum Food Safety Without Compromise

Insort’s Zero Touch Reject Technology sets a new standard in food safety and contamination removal by eliminating foreign materials without mechanical impact or air blasts. Instead, the system utilizes a high-speed trapdoor mechanism, ensuring the most reliable and precise removal of hazardous contaminants from the production line.

This innovative reject system is designed to handle even the most challenging foreign objects, including:

- Critical hazards like broken glass bottles, rodents, and plastics.

- Heavy or bulky items such as large stones, metal parts, and sticks.

- Lightweight contaminants like plastic film, cardboard, and paper.

Unlike traditional air jets or mechanical paddles, which may struggle with heavy or irregularly shaped materials, Insort’s Zero Touch Technology adapts dynamically. Depending on the size and location of the foreign object, the system automatically activates one or multiple high-speed reject gates, ensuring complete and efficient removal—without impacting or disturbing the remaining product stream.

By eliminating any physical contact with contaminants, Zero Touch Reject Technology guarantees unparalleled food safety, preventing dangerous materials from reaching the final product. This breakthrough technology ensures maximum reliability, efficiency, and product integrity, redefining food safety standards for the industry.