It‘s not just a Sorter.

It‘s your Food Safety Guarantee!

Sherlock Safeguard offers the most versatile inspection technology that combines uncompromising food safety with automation and product quality monitoring in one device.

With the latest generation of the high precision, advanced Chemical Imaging Technology (CIT® Gen3) and newest hyperspectral cameras – developed specifically for Insort – full spectrum real-time analysis is even more precise.

Combining CIT® Gen3 with high resolution cameras and optional conductivity sensors, the Sherlock Safeguard classifies foods based on chemical composition, color, shape, pattern, conductivity and much more.

This results in unprecedent performance of detecting all foreign materials – organic or inorganic – at the lowest possible product loss.

The Zero Touch Reject Technology ensure maximum safety in removing the detected foreign material eliminating bounce backs, misfires or other mechanical interferences.

Any foreign material, organic or inorganic, can be sorted out with unprecedented accuracy.

We Do Not Reinvent Existing Standards. We Change The Game!

- FM removal independent of size, shape, weight and density

- Any bulk food product – big or small.

- Any critical defect – big or small.

- Any foreign material – organic or inorganic

- Latest Chemical Imaging Technology CIT® 3rd Gen

- Artificial intelligence applied in real time

- End of Line Food Safety and critical control

- Enhanced software for most precise sorting results and improved usability

- Labor savings and quality control data

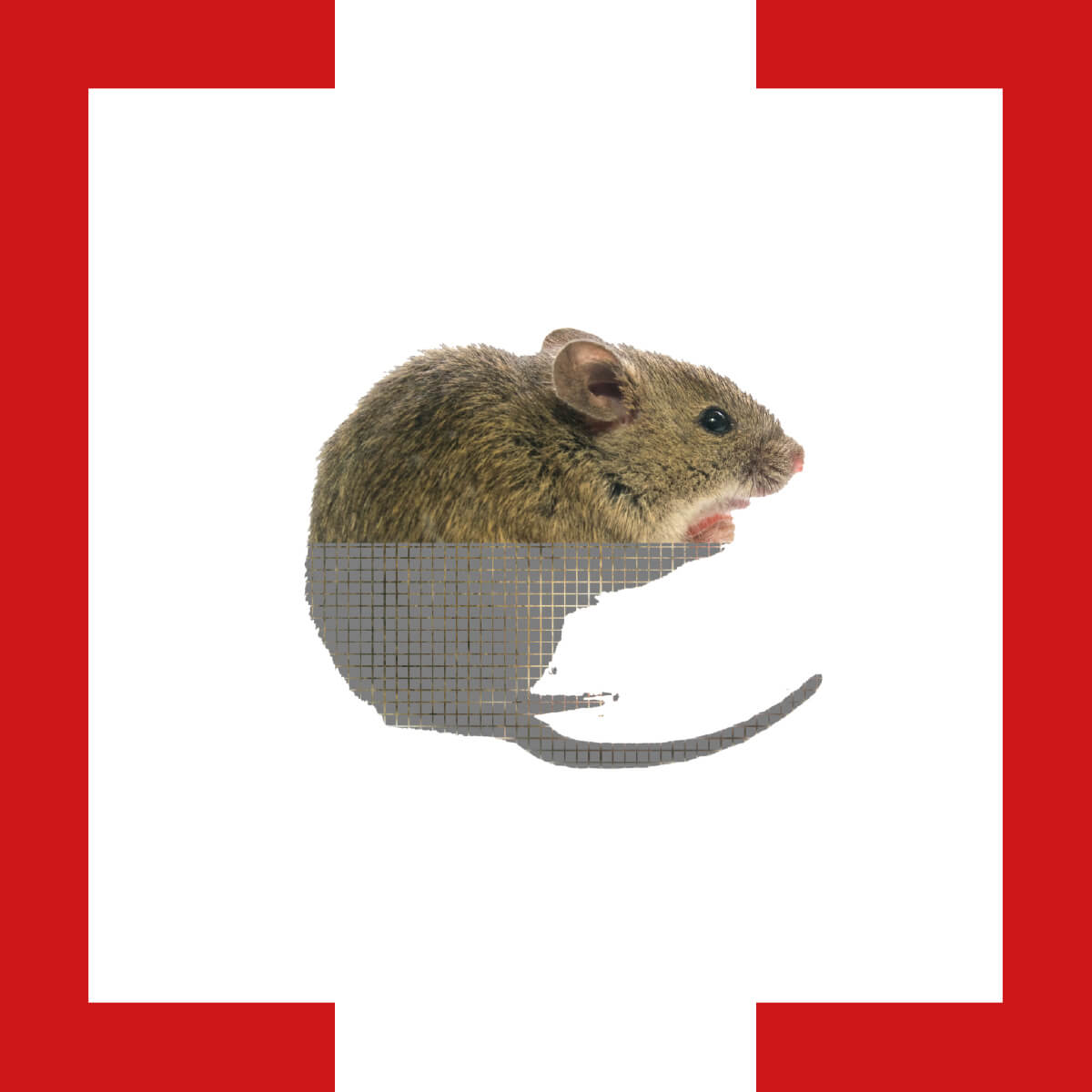

Some Application and Defect Examples

Technology that Makes the Difference

CIT’s chemical inspection capabilities brings us to new levels and possibilities of product inspection compared to any other optical eye out there such as lasers, various amount of cameras or Xray. Where other optical eyes focus on trading off the amount of bad in good vs good in bad; CIT’s approach is seeing and removing it with the highest reliability of the industry, no matter what product or defect and this at consistent levels even if there are seasonal product changes or product variety changeovers. CIT does not need any operator to constantly be monitoring and keeping the machine in balance.

For the first time, artificial intelligence in the most versatile form of Deep Neuronal Networks is applied in real time to analyse the collected image data. It creates algorithms that enable the detection of even the smallest visible product defects as well as defects invisible to the human eye, fast enough to eject them from high-speed product flows. This new disruptive technology opens unimaginable applications and performance levels for food processors.

InlineFOODLab 4.0 allows processors to optionally get quantitative chemical data of the product and the most reliable real-time inline quality data available in the industry. For example dry matter values in potato products. These chemical data can be combined with color or shape defect levels as well as with size values of the objects. Additionally, any foreign material can be recorded. This allows quality managers to have better tools to control the raw material as well as the finished product.

The Safeguard Zero Touch Reject Technology drops foreign bodies down through a trapdoor. No active mechanical touch or air blast needs to be applied to foreign bodies to remove them from the product stream, which guarantees removed with the highest reliability.

Critical (or hazardous) foreign materials like broken glass bottles, rodents, plastics and many more do no longer get the opportunity to enter the plant or make it into the final product for the customer. Difficult objects such as large or heavy stones, sticks or metal parts, and very light parts such as plastic film, cardboard and paper are all removed with highest reliability, compared to trying to remove these defects with air jets. Depending on the size and location of foreign materials, the system will automatically open one or multiple high-speed reject gates. This zero touch removal technology personalizes the opening time to remove these hazardous materials without striking with strong paddles or high pressure air.